APD Series Semi-closed High Precision Steel Frame Press

Key words:

Semi-closed high precision steel frame press

Classification:

- Product Description

- Standard/Optional

-

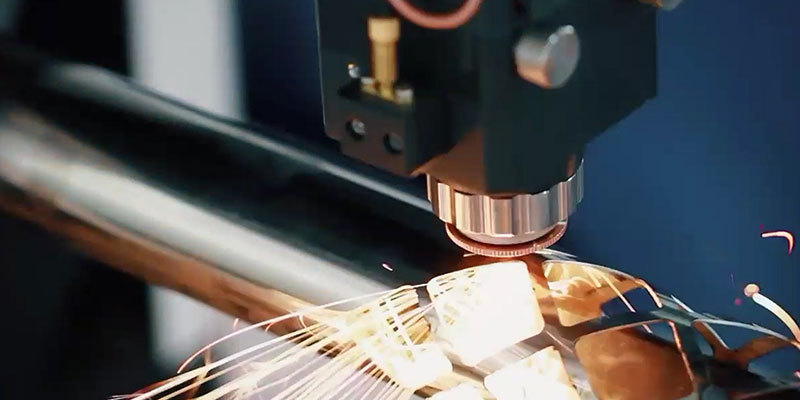

- Commodity name: APD Series Semi-closed High Precision Steel Frame Press

- product: SEMI-CLOSED HIGH PRECISION STEEL FRAME PRESS

Straight wall integrated frame suitable for precision continuous die machining. Get rid of shortcomings of open throat of C-type press frame,saving the maintenance cost of the die.

Product Features

• High-rigidity frame with long guide rails on the centerline and the support stroke to guarantee long-term dynamicstabllity precision and extend the service life of the die.

• The bottom area of the press is 15-25% larger than that of the C-type press, enabling the increase of the number of die engineering and improve the added value.

• High-torque pneumatic brake clutch for long life and low maintenance cost;no pollution,low noise,and environmentally friendly.

• High safety,high affnity,muti-function electronic control system.

• Applicable with a variety of automation ecuipment with easy operaton.

Technical parameters

Name

APD-80 APD-110 APD-160 APD-200 APD-260 Type

V H V H V H V H V H Tonnage

Ton 80 110 160 200 260 Rated tonnage point

mm 4 2 6 3 6 3 6 3 7 3.5 Stroke

mm 150 70 180 80 200 90 200 100 250 150 Maximum closed working height

mm 340 380 360 410 460 510 460 510 500 550 Number of strokes per minute

s.p.m 35-80 80-120 30-60 60-90 20-50 40-70 20-50 50-70 20-40 40-50 Slider adjustment volume

mm 80 80 100 110 120 Upper table size

mm 560x420x70 650x470x80 700x550x90 850x630x90 950x700x100 L ower table size

mm 930x550x90 1090x600x110 1190x800x140 1390x820x160 1550x840x180 Main motor

Kw. p 7.5 11 15 18 22 Sider adjustment mechenism

HP Electrical driving Applied air pressure

kg/cm2 6 6 6 6 6 Press (LxWxH)

mm 1300x1890x3000 1420x1985x3200 1600x2200x3500 1750x2500x3900 2780x1850x4470 Press precision

GB(JIS) Class I Die cushion capacity

Ton 3.6 6.3 10 14 14 Die cushion stroke length

mm 70 80 80 100 100 Die cushion effective area

mm2 450x310 500x350 650x420 710x480 810x480 -

Standard configuration

• Frequency converter

• Oil hydraulic overload protection device

• Electric slider adjustment device

• Electric die height indicator

• Slider and die balancing device

• Air source connector

• Secondary drop protection device

• Maintenance tool and tool box

• Instruction manual

• Power outlet

• Shockproof support

• 7 inch touch screen, electronic cam

• Angledisplay

• Tonnage measurement and protection device

Optional configuration

• Electric butter lubrication device

• Pneumatic die pad device

• Pre-load counter

• Pre-break counter

• Foot switch

• Quick die changer (die lifter,die clamp or die remover)

• Slider upper feeding device

• Misfeed detection device

• Photoelectric protection device

• Feeder (air, machinery and NC)

• Leveling machine

• Rack

• Mechanical arm

• Die lighting device

• Left/right feeding device

• PAC100 control system

• Human-machine control system

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Deep understanding of the product

Yitian Seiko Machinery National Service Hotline: 86-574-86198812Welcome manufacturers to negotiate!

Service Hotline:

Zhejiang Etone Precision Machinery Co., Ltd.,

Address: No.327 South of Tinghai Road, Yinzhou EconomicDevelopment Zone, Yinzhou Distrist, Ningbo, China

Telephone: 86-574-86198812,86-574-86198845

Fax: 86-574-86198900

E-mail:sales@china-etone.com

WeChat Public Number

![APH Series High Speed Gantry] Punch APH Series High Speed Gantry] Punch](https://omo-oss-image.thefastimg.com/portal-saas/new2023120119444055392/cms/image/9770aa5f-090f-401d-a27f-3bd58760b129.jpg)