APZ Series Knuckle Link Type High Speed Precision Press

Key words:

Knuckle Link Type High Speed Precision Press

Classification:

- Product Description

- Standard/Optional

-

- Commodity name: APZ Series Knuckle Link Type High Speed Precision Press

- product: KNUCKLE LINK TYPE HIGHSPEED PRECISION PRESS

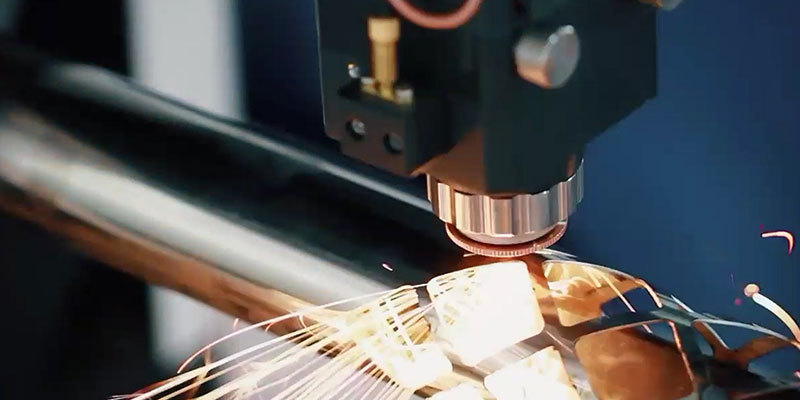

A press machine suitable for fine precision high speed stamping, which has helped realize the minimized thermal displacement and punch penetration, as well as the striking effect, by introducing the knuckle mechanism. The standard model, with its high reliability. The line-up covers the range from 150T to 1500T, wide series, high-speed model.

Product Features

• By maximizing the knuckle mechanism feature, simplifying the structure, and increasing the productivity, this knuckle press machine is designed for high igidity and themal balance.

• The perfect symmetrical balancer allows die height displacement due to SPM changes, as well as the BD.C. displacement due to the 1st and 2nd punches, to be suppressed to the minimum.

• The balance mechanism that countervails left and right components of force, and double slide- guiding,system composed of 2 plungers and 8 faces needle bearings, have improved the slide capacityof eccentric load -resistant furthermore.

• The new non-backlash clutch/ brake, with its long duraillity and litle noise, achieves quieter operation.

• The lateral bolster size in this wide series is 1,100mm/60ton, 1350mm/ 60ton, 1200mm/80ton, 1 ,500mm/ 80ton wide type,which is the maximum in each class.

• In terms of features, operation performance has improved by lengthening the slide adjustment amount,and displaying the crank angle in the electron rotary system.

Technical parameters

Madel

Model specifications

APZ-15H

APZ-30

APZ-40

APZ-40 W

APZ-60

Tomage

15

30

40

40

60

Sroke Length

mm

10

20/25/30

20/25/30/32

20/25/32/40

20/25/32

Strokes Per Mnute

SPM

200-1800(2000)

200-1200/1050/900

180-1000/900/850/850

180-850/800/700/700

100-750/750/650

Shutheight

mm

220

240

240

240/240/240/235

300

Shutheitht Adjustment

mm

30

40

50

50/50/50/45

80

Side Area

mm

500x260

600x300

750 × 340

950 x 450

1030 × 500

Boster Aree

mm

500x360

600x400

750 × 500

950 × 450

1100 × 600

Bloster Thinkness

mm

80

90

120

120

140

Bed Opening

mm

350x50

400 × 100

560 × 120

790x600

840 × 120

Bester Opening

mm

250x40

350 × 60

500 × 100

790 × 100

780 × 80

Main Motor

kw

15

11

15

185

22

Madel

Model specifications

AP7-60 W

APZ-8C

APZ-80 W

APZ-125

APZ-125S

APZ-150

Tomage

60

80

80

125

125

150

Sroke Length

mm

25/32/40

20/25/32/36

25/32

25/36

25/36

30/36

Strokes Per Mnute

SPM

100-700/600/450

120-700/600/550/500

120-500/450

100-400/35

100-600/400

100-400/350

Shutheight

mm

340/340/335

320

320

350

350

350

Shutheitht Adjustment

mm

80/80/75

80

80

80

80

80

Side Area

mm

1280x500

1080x580

1380 × 580

1480 × 600

080x 600

1480 × 600

Boster Aree

mm

1350 x 600

1200x800

1500x800

1600 x 900

1200 x 900

1600x900

Bloster Thinkness

mm

140

160

160

180

180

180

Bed Opening

mm

1050 x 120

900x160

1200 × 160

1300x160

960x 160

1300x160

Bester Opening

mm

1000 × 80

860 x120

1160x 120

1260x 120

9200x120

1260 x 120

Main Motor

kw

22

30

30

37

37

37

-

Standard Accessories

• lnverter type variable speed mainmotor

• Combination type air friction clutch /Brake

• Dynamic balancer

• Eectronic rotary cam switch

• Electronic crank angle indicator

• Touch Panel 8.4 inch

• Speed meter

• Total counter (9-digit electronic type)

• Preset counter (9-digit electronic type)

• Hour meter (7-digit electronic type)

• Operation box selfstand type

• Motor reverse device

• Missfeed plug/socketl withchangeover switch)

• Electric slide adjustment device

• Micro inching (reverse available)

• Pneumatic control unit

• Circulation type lbrication unit

• Gripper feeder

• Safety door

• Both hands push buttons

• Shock absorber

• Oil heater cooler

• Stock end stop switch (proximity)

• Stock oil tank (with solenoid valve)

• Stock guide (to the end of bolster)

• Over-tension stop outlet

• All stop circuit (without fimer)

• 200V outlet

• Air outlet (1/4B)

• Working light

Optional Accessories

• Precision Camshaft feeding machine

• Material Cell guide 1 pc

• Bottom dead center precision detector

• Die lifting arm

• Die removal arm

• Waste collector

• Materil oiling devi

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Deep understanding of the product

Yitian Seiko Machinery National Service Hotline: 86-574-86198812Welcome manufacturers to negotiate!

Service Hotline:

Zhejiang Etone Precision Machinery Co., Ltd.,

Address: No.327 South of Tinghai Road, Yinzhou EconomicDevelopment Zone, Yinzhou Distrist, Ningbo, China

Telephone: 86-574-86198812,86-574-86198845

Fax: 86-574-86198900

E-mail:sales@china-etone.com

WeChat Public Number

![APH Series High Speed Gantry] Punch APH Series High Speed Gantry] Punch](https://omo-oss-image.thefastimg.com/portal-saas/new2023120119444055392/cms/image/9770aa5f-090f-401d-a27f-3bd58760b129.jpg)